The Rapid temperature change test chamber is used for testing the performance of materials in various environments and testing the heat, cold, dry and moisture resistance of various materials. Suitable for electronic, electrical, mobile phone, communication, instrument, vehicle, plastic products, metal, food, chemical, building materials, medical, aerospace and other products testing quality.

The Rapid temperature change test chamber is used for testing the performance of materials in various environments and testing the heat, cold, dry and moisture resistance of various materials. Suitable for electronic, electrical, mobile phone, communication, instrument, vehicle, plastic products, metal, food, chemical, building materials, medical, aerospace and other products testing quality.

The Rapid temperature change test chamber is suitable for the safety performance test of electronic components to provide reliability test, product screening test, etc. At the same time, through this equipment test, the reliability of the product and the quality control of the product can be improved. Rapid temperature change test chamber is the necessary test equipment for aviation, automobiles, home appliances, scientific research and other fields, to assess and determine the parameters and performance of electrical, electronic, automotive electrical appliances, materials and other products, after the temperature environment impact changes in the high and low temperature test, the adaptability of use, suitable for schools, factories, military, research sites, and other units.

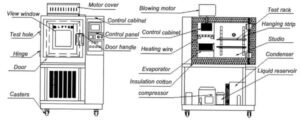

1. The Rapid temperature change test chamber has beautiful appearance, reasonable structure, advanced technology and exquisite material selection, and has simple and convenient operation performance and reliable equipment performance. The equipment is divided into three parts: high temperature chamber, low temperature chamber and test chamber. It adopts a unique thermal insulation structure and heat storage and cold storage effect. The object to be tested is completely stationary during the test. The hot and cold air path switching method is used to introduce the cold and hot temperatures into the test area. Thermal shock test purpose.

2. The most advanced measurement device is adopted. The controller adopts a large color LCD human-machine touch dialogue LCD human-machine interface controller. It is simple to operate, easy to learn, stable and reliable, and displays complete system operation status and execution in Chinese and English. and set the program curve. With 96 independent test specifications, the impact time is 999 hours and 59 minutes, and the cycle period can be set from 1 to 999 times. It can realize automatic operation of the refrigerator, realize automation to the greatest extent, reduce the workload of the operator, and can automatically operate at any time Start and stop work operation;

3. There is a test hole with a diameter of 50mm on the left side of the box, which can be used for testing components with external power load wiring. The function of three different conditions of high temperature, low temperature and hot and cold shock can be independently set. When executing the hot and cold shock conditions, the two-tank or three-tank type and cold punching or hot punching can be selected for impact function, with high and low temperature Testing machine functions.

4. It has a fully automatic and high-precision system loop, and any movement of the machine is completely P.L.C locked. All are controlled by P.I.D automatic calculation, with high temperature control accuracy. The advanced and scientific air circulation circulation design makes the indoor temperature uniform and avoids any Dead ends; complete safety protection devices avoid any possible safety hazards and ensure the long-term reliability of the equipment

5. The number of cycles and defrosts can be set for automatic (manual) defrosting. The air outlet is detected and controlled by the return air sensor. The switching time of the air door mechanism is completed within 10 seconds, and the recovery time for hot and cold shock temperature is completed within 5 minutes. It has status display and curve display during operation. When an abnormal situation occurs, the fault point and cause will be automatically displayed on the screen and troubleshooting methods will be provided. It also has an emergency shutdown device when the input power is found to be unstable.

6. The refrigeration system adopts a cascading high-efficiency low-temperature circuit system design. The refrigeration unit uses compressors imported from Europe and the United States, and uses green environmentally friendly (HFC) refrigerants R507 and R23 with zero ozone coefficient. Super safety protection function: power overload protection , Leakage protection, control circuit overload, short circuit protection, compressor protection, grounding protection, over-temperature protection, alarm sound prompt, etc.

| Model | BT-80(A-F) | BT-150(A-F) | BT-225(A-F) | BT-408(A-F) | BT-800(A-F) | BT-1000(A~F) |

| Internal size WxHxD(cm) | 40x50x40 | 50x60x50 | 60x75x50 | 60x85x80 | 100x100x80 | 100x100x100 |

| External size WxHxD(cm) | 120x165x115 | 130x170x125 | 140x185x130 | 165x195x155 | 185x200x175 | 190x210x185 |

| Weight (about) | 150KG | 180KG | 250KG | 350KG | 500KG | 520KG |

| Temperature range | Low temperature: A: +25 °C B:0°C C:-20°C D:-40°C E:-60°C F:-ZO°C) High temperature: 100°C(150°C) |

| Humidity range | 20%~98% R.H. (10%~98%R.H); (5%~98% R.H is a special selection condition) |

| Distribution accuracy | 0.1P 0.1%R.H./±2.0P ±3.0%R.H. |

| Temp and humi control accuracy | ±0.5t) ±2.5%R.H. |

| Heating/cooling time | Heating about: 3°C/min Cooling: 1°C /min |

| Internal and external materials | The inner and outer boxes are made of SUS304# stainless steel plate |

| Insulation material | High temperature resistant high density ethyl chloroformate foam insulation material |

| cooling system | Air-cooled / single-stage compressor (-20°C); two-stage compressor (-40°C – 70 °C) |

| Safety device | No fuse switch, compressor overload protection, super humidity over temperature protection, water shortage alarm protection |

| power supply | AC220V 50/60Hz & 1 # AC380V 50/60Hz3§ |

1. Reasonable structural design, rapid cooling rate.

2. Imported refrigeration system, internal with SUS#304 high temperature resistant stainless steel.

3. More than 30% energy saving is achieved.

4. The test specimen can be easily observed via observation window,

5. Easy to Operate, install and maintain.

6. ational Construction and fast cooling rate

7. Frequency conversion control of wind speed.

8. Adopts international brand of imported parts for cooling system to improve operation reliability

9. Touch screen controller, friendly Man-Machine interface and safety device to ensure simple operation and easy maintenance.

| GB/Bb T2423.2-89 high temperature test method | GB2423.1-89 test A: low temperature test method 6 |

| Ab IEC60068-2-1 low temperature test method | GJB150.4-1986 test at low temperature |

| EIA – 364-59 test at low temperature | IEC60068-2-38 temperature cycle |

| IEC60068-2-78 constant temperature | IEC60068-2-30 temperature cycle |

BOTO GROUP LTD. is a professional manufacturer of various kinds of testing equipments over 30 years, such as environmental test equipment, Industrial Hot Air Drying Ovens, UV Aging Test Chambers, Industrial Muffi Furnaces, Adhesive Paper Packing Testers,

Plastic Rubber Testers, Hardness Testers, universal test machine, Checkweigher Machine, Metal Detectors The test service integrating design, research and development, production, sales, service and construction.

No.689,Xiwang Road,Jiading District,Shanghai,201800,China